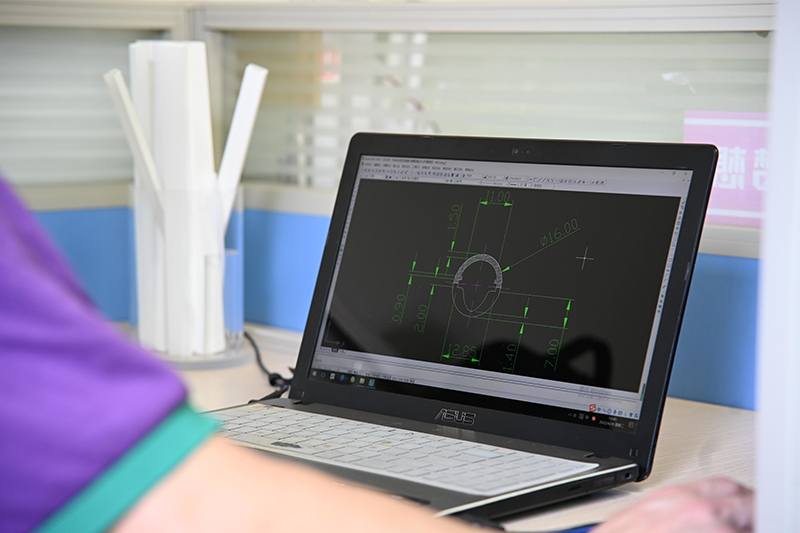

1.Engineering and CAD Design Support

Our CAD designers use state of the art 4-axis wire EDM programming software and can modify an existing design or can help you create an original design. Our engineering design team will review your design and give you advice regarding possible material choices, type of extrusion process, tooling, and inspection procedures in order to help you design a quality prototype sample.

2.Plastic Extrusion Tooling Services

In addition to a well-engineered design and selection of the ideal material, a quality plastic extrusion project requires the correct extrusion tooling. Custom tooling for your extruded product is designed and developed by our experienced engineers. This tooling allows us to manufacture the top-quality custom plastic extrusion for any industry.

3.Strict Quality Controls

Production department warrant to make strict quality controls in every step of the production process, by the sampling and measurements method, the products are tested with high-tech equipment.

Ø Electron Microscope: Test the product’s thicknesses and the layer of co-extrusion.

Ø Optical test equipment: Test the high transmittance haze.

Ø Xenon test equipment: Used to accurately simulate the effects of weathering, to determine mechanical and optical changes.